In brief

Presentation

The fast-moving industry of polymers is based on innovation and new markets. Always facing new challenges, talents are searched to develop new trends such as energy efficient processes, bioplastics manufacturing and plastics recycling. Our Processes and Polymers program offers skills for the petrochemical and polymer companies, in a multicultural environment: a recognized Master program where you will embrace a sector where innovation knows no bounds!

The key points of the program

Career prospects for graduates

Program & planning

Program

Chemical engineering fundamentals, operation and safety management for everyone

- Design and operational issues of main equipment: heat exchangers and rotating machinery

- Chemical reactor technologies design and operation

- Polymer reaction engineering

- Separation processes

- Engineering projects in petrochemistry: PFD, PID, project cost estimation and management

- Risk management and process operation safety

Processes for everyone

- From Oil and Gas to Hydrogen processes

- Base chemicals and petrochemicals intermediates

Experience sharing module

Development of soft skills

? Elective path1: Plastics chain value

- Plastic chain value & manufacturing

- Overview of plastic processing

- Recycling processes

? Elective path2: Innovative and Sustainable chemicals

- How to create a new process ever more sustainable (ecodesign)

- Biosources markets and Bio-polymers processes

- Environmental impact of polymers through Life Cycle Analysis

Planning

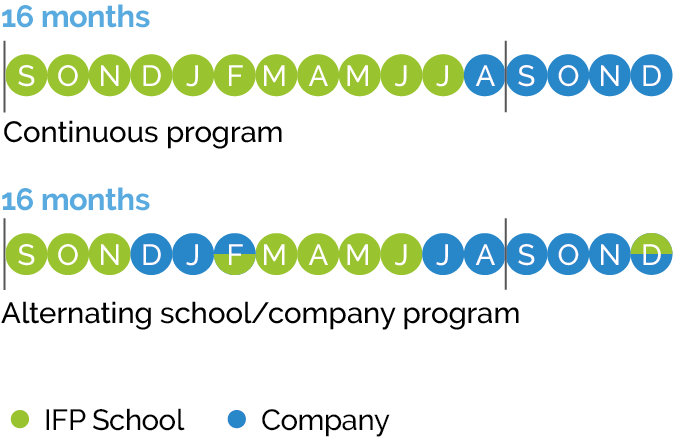

The two examples of schedules shown below correspond to the most frequently encountered cases for students in this program:

-

16-month continuous program for students with a 4- or 5-year engineering degree

-

alternating school/company 16-month program for students with a 5-year engineering degree

There are other possible cases, such as:

-

a 22-month alternating school/company program for students in their penultimate year of a major European school or university having signed a double-degree agreement with IFP School

Career opportunities

Businesses

-

Process development

-

Product development

-

Project engineering

-

Energy optimization

-

Operations and HSE management

-

Logistics and sales

Jobs

- Production engineer in petrochemical complexes: assists the operational manager, ensures day-to-day technical management of the unit, and is the liaison with development, research, logistics and other departments.

- Process development engineer: ensures a process technology watch and anticipates future needs ensuing from technological and regulatory changes, helps plants and contributes to experience sharing between sites, participates in R&D programs by providing process skills, and maintains contacts with the company's various entities.

- Process engineer (in a large engineering firm): sizes petrochemical, polymer and refining units (equipment, instrumentation and piping), simulates and optimizes operation of the units using a number of industry-specific software programs, and participates in various project reviews (HAZOP, etc.) and unit startups.

- Process engineer (engineering department in a petrochemical complex, a refinery and an R&D center): monitors one or more complex units, and in conjunction with the operator, participates in technical monitoring, in operations optimization and in investment projects to improve operation, safety and security.

- Product development engineer: ensures a product technology watch and anticipates future needs by maintaining a customer focus, conducts assistance assignments on customer premises, participates in R&D programs by providing product skills, and maintains contacts with the plant's various entities.

- Product manager (in plastics processing): participates in the drafting of the specifications for manufacturing new products and searches for materials and conversion technologies likely to meet specifications from an economic standpoint.

Funding & sponsorships

Typical class profile

Students in this program are almost all sponsored by companies (through sponsorships or apprenticeships) that finance their living expenses during the academic period and contribute towards their tuition.

Main sponsors

Among these companies, the following have been IFP School partners in recent years (non-exhaustive list):

- Arkema

- Axens

- Bostik

- ExxonMobil

- IFPEN

- Ineos

- Infineum

- Lyondell Basell

- Michelin

- Plastic Omnium

- S-Oil

- Technip Energies

- TotalEnergies